Non-Asbestos Gasket Jointing Sheets

Suitable for water/oil resistant gasket material for light to medium loading. Suitable for low operating pressure, e.g. transformers, compressors and also used for easily deformable components with low surface pressure like valve covers and pans in internal combustion engines.

| Material Composition: \n (Type of fibres) | Aramid Fibre, Mineral Fiber . |

| Binders: | NBR |

OPERATING CONDITION : | |

| Max.Peak Temp | 300°C |

| Max. Continuous Temp | 220°C |

| Max.Continuous Temp.with steam | 160°C |

| Max. Operating Pressure | 80 Kg/cm2 |

- 1/64

- 1/32

- 1/16

- 3/32

- 1/8

- 3/16

- 1/4

- 60″X60″ SHEETS

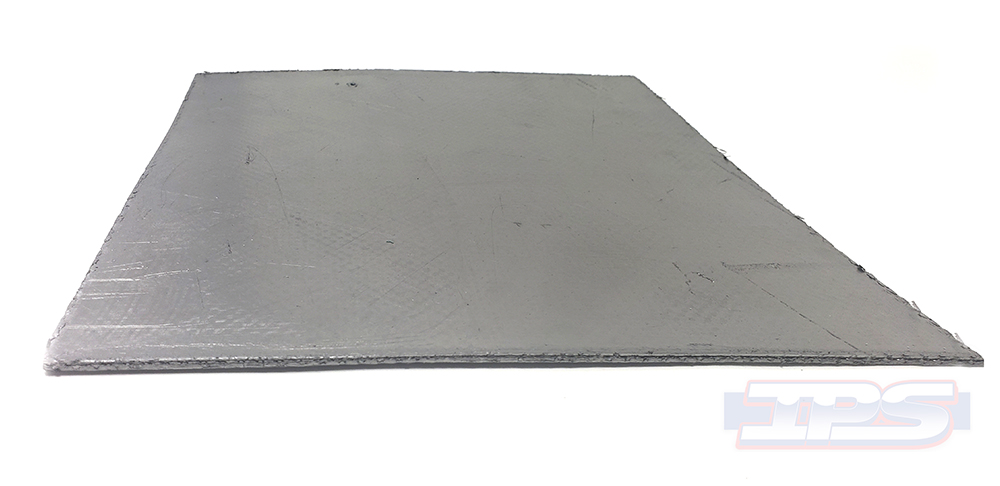

CNA2000-WG:

Compressed Non-Asbestos Sheet with Wire Mesh and Graphited.

Compressed jointing based on high quality Non-Asbestos Fibre with a nitrile rubber binder. reinforced with S.S wire insertion and both side coating graphite.

Uses: General purpose material with excellent chemical resistance and mechanical properties. Suitable for use with air, steam, oil, fuels, gases (including Oxygen) and potable water applications.

Operating Guidelines | |||

Maximum Temperature | 350C | ||

Maximum Pressure | 120 bar | ||

Maximum Steam Temperature | 200C | ||

Typical Original Properties (for all stress relaxation BS 7531 (400 Nmm2 ) DIN 52913 (500 N/mm2) ) | Thickness | ||

1.5mm Thick | 2.0mm Thick | ||

Specific gravity | 1.80 |

| |

Compressibility | ASTM F36A | 9% |

|

Recovery | ASTM F36A | MIN. 50% | Min. 50% |

Stress Relaxation | BS 7531 DIN 52913 | 23 N/mm2 – |

|

Gas Leakage | DIN 3535/6 | 0.4 ml/min |

|

Typical Properties after Fluid Immersion (1.5 & 2.0mm Thickness) | |||

ASTM Oil 3 | 5 hours 150C | 0-5% | |

- 1/16

- 3/32

- 1/8

- 60″x 60″ sheet

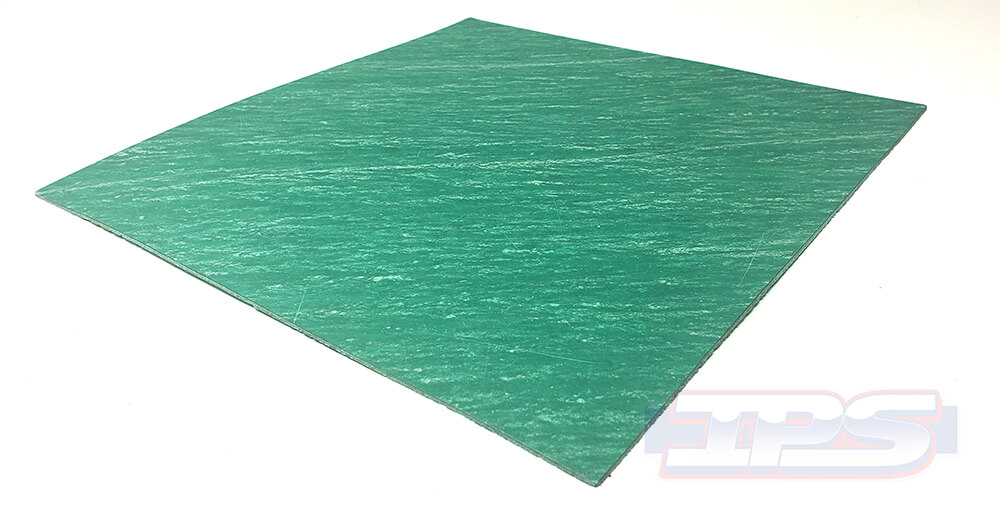

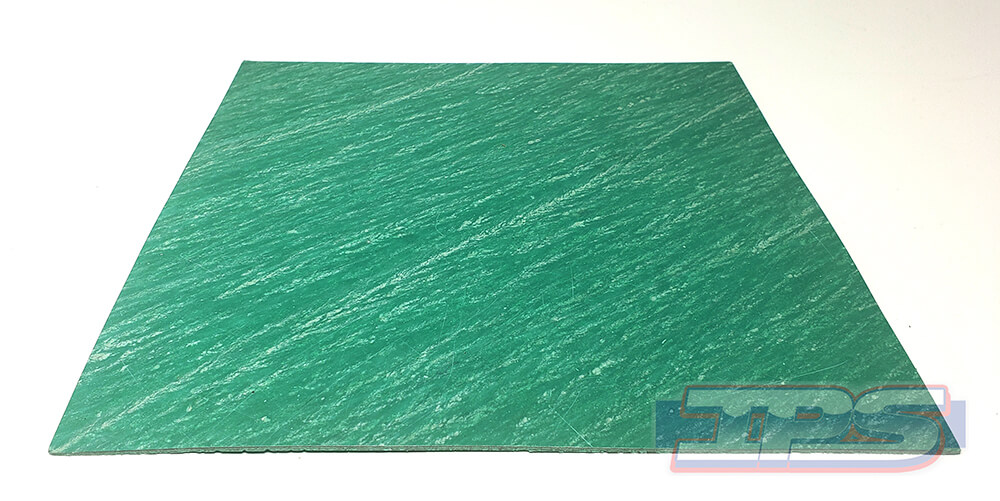

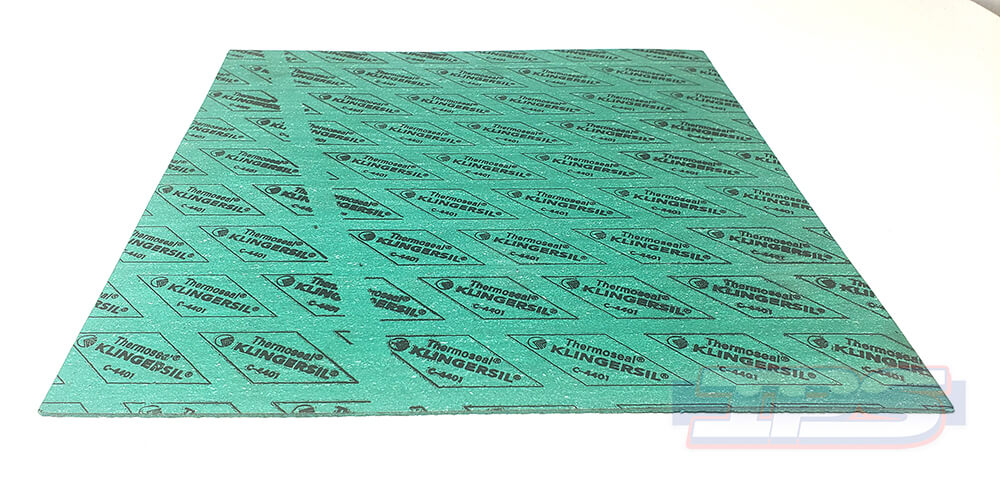

KLINGER C-4401

- Synthetic Fiber

- Nitrile Binder

- Excellent Sealability

- Excellent Chemical Resistance

- Good Creep Relaxation

- General Purpose Sheet

Creep Relaxation ASTM F38B (1/32″) | 20% |

Sealability ASTM F37A (1/32″) | < 0.25 ml/hr |

Gas Permeability DIN 3535/6 | < 0.5 ml/min |

Compressibility ASTM F36J | 7% |

Recovery ASTM F36J | 50% mínimum |

Klinger Hot Compression Test Thickness Decrease 73°F (23°C) Thickness Decrease 572°F (300°C) | 10.5% initial 17% additional |

Weight Increase ASTM F146 after immersion in Fuel B 5h/73°F (23°C) | 10% máximum |

Thickness Increase ASTM F146 after immersion in ASTM Oil 1, 5h/300°F (149°C) ASTM Oil IRM903, 5h/300°F (149°C) ASTM Fuel A, 5h/73°F (23°C) ASTM Fuel B, 5h/73°F (23°C) | 0-5% 0-5% 0-5% 0-7% |

Dielectric Strength ASTM D149-95ª | 14 kV/mm |

ASTM F104 Line Call Out | F712121B3E12K6M5 |

Leachable Chloride Content FSA Method (Typical) | 100 ppm |

Density ASTM F1315 | 112 lb/ft³ (1.8 g/cc) |

Color(Top/Bottom) | Green |

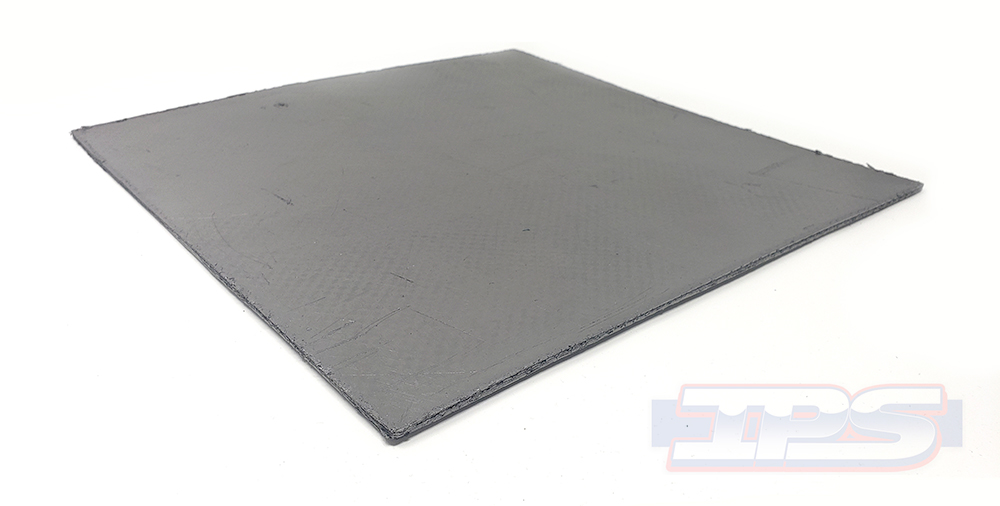

SG80-B

Reinforced Graphite Composite Cylinder Head Gasket Sheet Graphite Composite Cylinder Head Gasket Sheet

Manufactured from expanded graphite sheet with tanged (perforated) of 0.18mm ~ 0.25mm tinplate inserted reinforcement. It is best material for cylinder head gasket, exhaust gasket and other engine gasket seal.

Density: | 1.30~1.45g/cm3 |

Carbon Content: | 98% Min. |

Compressibility: | 15% Max. |

Recovery: | 55% Min |

ASTM F146 3# OIL 150 C 5h Thickness increase: | 15% Max |

Weight increase: | 10% Max |

ASTM F146 Fuel B R.T 5h Thickness increase: | 10% Max |

Weight increase: | 10% Max |