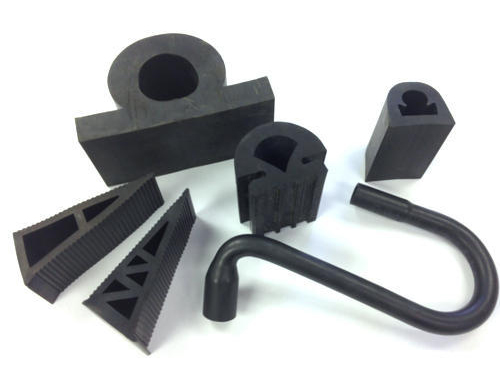

An extruded rubber product differs from a molded rubber product in that the uncured rubber is forced through a die of the desired cross-section under pressure from an extruder. The extruded product is then vulcanized, or cured, in a heated pressure vessel known as an autoclave. Extruded parts can be made in sizes ranging from 1/8″ in diameter to a rectangular cross-section of up to 6″ by 12″ and in continuous lengths of up to 60 feet.

The manufacture of extrusions into circular or rectangular gaskets can be accomplished by means of butt- or corner-vulcanized splices.

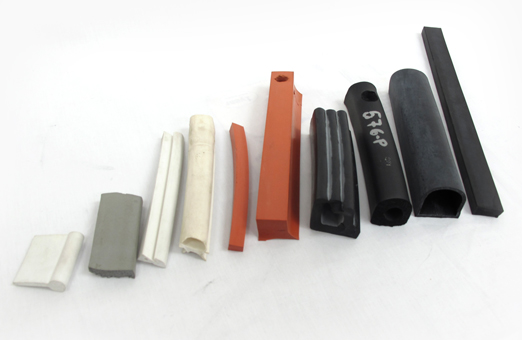

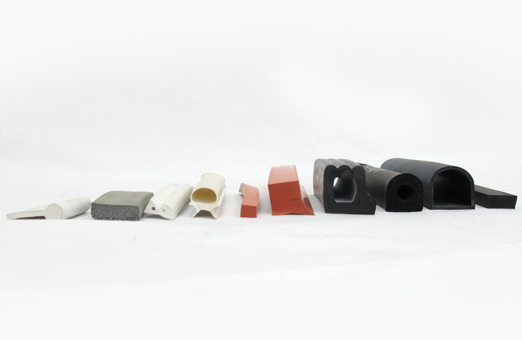

Examples of Extrusions

• O-Ring Cord

• Rectangular

• Square

• Odd Shapes

• Tubing

• Pads

• Bumpers

• Channels

• “P” Shapes

IPS has the extensive experience with the following materials:

• EPDM

• Neoprene

• Natural Rubber

• Polyurethane

• Viton

• Nitrile

• Silicone

Custom profiles are our specialty…

• Custom designed compound formulations to meet your application requirements

• Quotes in just hours, not days

• Straight lengths up to 60′

• Lower minimum orders